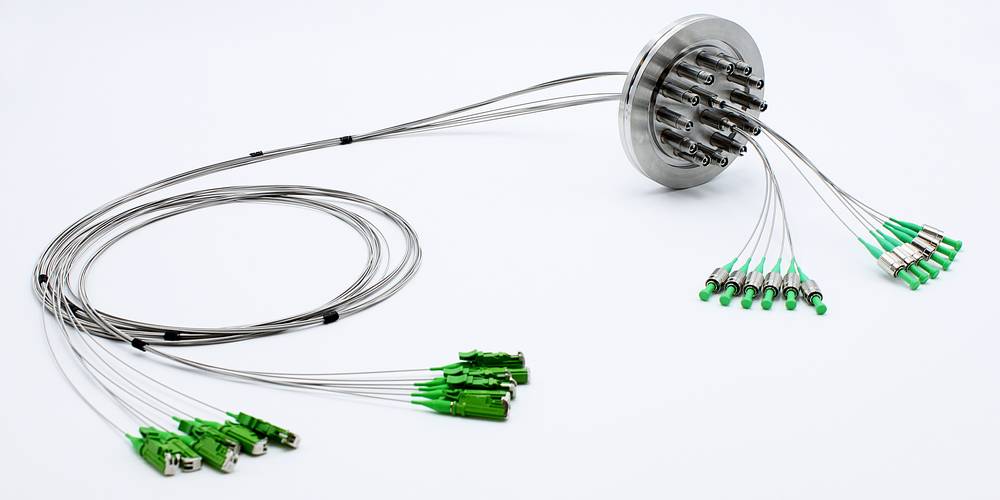

Custom-madeSolution

We design products to your specifications

You need a custom-made product to fit in your special environment, for which there is currently no off-the-shelf solution available? SEDI-ATI helps you overcome your challenges!

Get advice and ongoing support from our team

Our mission at SEDI-ATI is to design and manufacture turnkey fiber-optic solutions to enable you to transport photons in any environment, whatever your constraints!

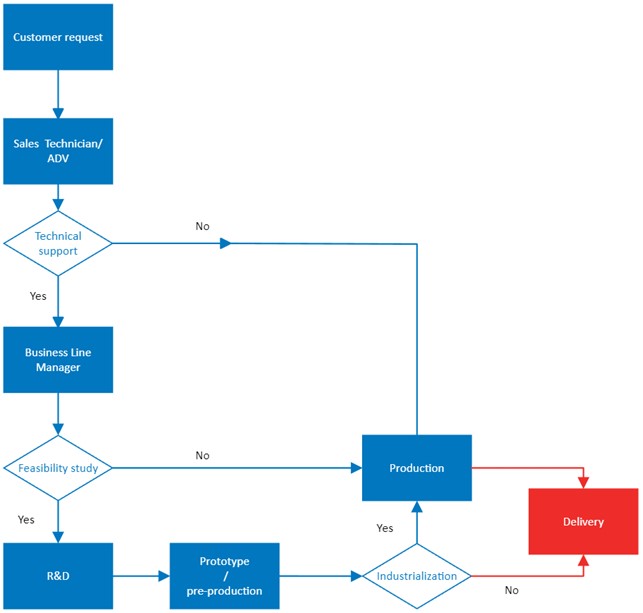

Technical support and Research & Development (R&D) are the two pillars that enable SEDI-ATI to design the solution dedicated to your application in harsh or extreme environments.

The sales team, made up exclusively of experienced technical sales staff, has a wealth of technical experience and can guide you in the technical and technological choices to be made during the initial discussions about your project.

The Business Line Manager (BLM) provides technical support, drawing up technical drawings, manufacturing lists, production times, cost prices and delivery times on receipt of orders. In addition, when the customer’s project requires a feasibility study, it is the BLM who transmits the request to R&D.

The customer is kept informed of the status of his request at every stage, from receipt by the sales representative to delivery, via each stage of the customer’s journey (intervention by the BLM, dispatch to production or feasibility request in R&D, then production and dispatch).

SEDI-ATI Fibres Optiques also offers 360° support, with a post-sales service to advise you or answer any questions you may have (assembly set-up, fiber deployment, recommendations, etc.).

Advices

Benefit our high-tech production tool

The SEDI-ATI Fibres Optiques production plant has been custom-built to meet your most complex challenges and demanding applications.

We have equipped the factory with :

- Two clean rooms, one of which is ISO class 7,

- Two evaporation chambers,

- Test chambers: helium hermeticity, pressure tests up to 1,000 bar and tensile strengh tests,

- Programmable environmental chambers,

- Glass processing stations,

- Sub-millimeter spectrophotometers and reflectometers,

- Tunable lasers, power lasers and etching lasers,

- Polishing and assembly benches,

- High-precision drilling and milling machines,

- Solidworks CAD stations.

We have also expanded our production workshops to increase our production capacity and meet growing demand.

We can meet your most extreme constraints (pressure, vacuum, temperature variations, hostile environments, shocks, etc.), whether for defense, aerospace, energy, industry, medical or datacommunication.

Take part in the design of your solution

We offer custom-made solutions for extreme applications and environments. Because we design and manufacture our optical components almost exclusively according to our customers’ specifications, our wide range of products is ultimately the result of a careful study of their requirements.

The challenge is to design the best-performing, most reliable and most robust fiber-optic component to withstand extreme physical and environmental constraints.

Your assemblies can be customized, from the optical fiber to the output connector, including the type of cladding and coating, the connectors, and the manufacturing materials used. Each component is selected according to the final application of the assembly, to ensure optimal, long-lasting use and the best possible results.

Our participation in numerous large-scale projects means that we can quickly develop new technological building blocks to meet your needs.

Innovate with our R&D team

By listening to and understanding our customers’ markets, we are able to design tomorrow’s innovative products. Every year, our R&D team develops new technological building blocks to anticipate our customers’ future needs.

The R&D department has a strong presence within SEDI-ATI Fibres Optiques, since in addition to developing new technological bricks, it is also called upon to design mechanical parts, carry out feasibility and qualification studies, etc. It therefore works in close collaboration with the sales and marketing department. It works closely with the sales team to define THE product you need.

Our R&D Department boasts a team of multidisciplinary experts, as well as sophisticated assembly resources, measurement equipment and test benches.

This team is made up of:

- A director ;

- Technical managers ;

- Design managers;

- R&D engineers;

- And R&D technicians.

These highly qualified professionals excel in various technical fields, such as the shaping and assembly of complex fiber optic components, the design and production of sub-assemblies resistant to complex and extreme environments, opto-mechanics, micro-mechanics, metrology, instrumentation, non-linear optics and qualification testing.

Involved in several simultaneous projects, this team operates in project mode according to PMP standards, and applies ISO 9001-compliant product development processes. It has the capacity to support its customers in the development of complex solutions from the lowest level of technological maturity TRL0.