MonitoringTransformer

Optical assembly for electrical transformer

SEDI-ATI has developed optical assemblies which, combined with the customer’s electronic equipment, enable real-time monitoring of the system’s health. They are installed inside the transformer itself. This solution consists of an assembly of several optical fibres and a hermetic feedthrough.

Majorconstraints

- High-voltage : up to 25 kV,

- High pressure: up to 12 bars,

- Corrosive and abrasive environment: SF6 or mineral oil,

- Hostile atmosphere: moisture,

- Temperature variations: from -40 °C to +90 °C,

- Space constraints: long fiber lengths up to several tens of meters.

Thechallenge

Optimizing the electrical production by measuring the variations in temperature and in current within the electrical insulators and transformers.

Very expensive, insulated electrical transformers should be monitored

Insulated electrical transformers are one of the most critical and expensive investments in today’s electric power transmission and distribution systems. Their reliability typically depends on their insulation condition.

Any overlooked critical fault generated inside a power transformer may lead to a transformer catastrophic failure which could not only cause a disruption to the power system but also significant equipment damage. The cost of a failure can easily reach multi-million dollars.

Therefore, monitoring the health state of transformers with accuracy and prompt information is the critical prerequisite to predict fatal failures, optimize the maintenance, and make a vital decision on a transformer with suspicious conditions.

Advantages and applications of dielectric materials

Fiber optic cables made of dielectric materials, such as fused silica glass, are excellent candidates for online and real-time monitoring. Indeed, besides their small size and light weight, they offer unique advantages such as immunity to electromagnetic interferences, high sensitivity, stability, repeatability, durability against extreme environments, and fast response. And they can be submerged in transformer mineral oil or SF6 gas.

Such fiber-optic assemblies help measure various physical parameters like temperature, current, pressure, acceleration, refractive index of the insulating medium, moisture content in the oil, and a host of other applications.

Safe and permanent insulation are mandatory

In high voltage transformers, a decisive significance is attributed to a secure and permanent insulation. The mineral oil and SF6 gas are good insulating materials. However, due to some inevitable factors such as electrical and thermal stresses as well as mechanical aging, the insulating medium inside a high-voltage transformer might be affected. For instance, some unwanted particles like water and gas can contaminate the oil. As a result, insulation strength gets reduced that may result in partial discharges and hot-spots in transformer oil.

Estimate the health of the transformer by measuring temperature and current changes

Partial discharge is not only a precursor of insulation degradation but also a primary factor to accelerate the deterioration of the insulation system in a transformer. Monitoring of partial discharge activities through the measurement of changes in temperature and in current in the transformer insulating medium has been proven to be an effective procedure for transformer health state estimation.

The potential of multiplexing with a single signal conditioner

Moreover, such fiber-optic assemblies have great potential for multiplexing, which means that distributed electrical and thermal fault detection can be achieved with a single signal conditioner, hence providing the temperature profile of the winding, as well as enabling the localization of the partial discharge origin.

Our customized offer

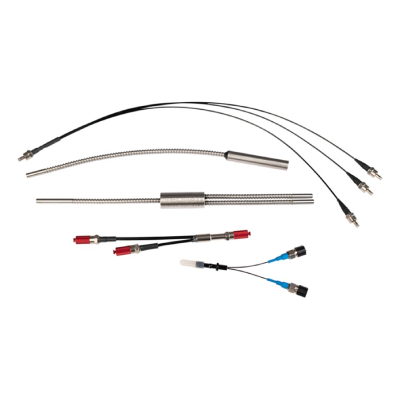

SEDI-ATI has built optical fiber cables made of multimode silica glass, aimed to be placed inside the transformer tank. An inline hermetic fiber optic feedthrough on the transformer tank wall allows to safely pass the fiber optic cable through the tank wall without affecting the insulation integrity of the transformer.

SEDI-ATIsolution

Fiber optic assembly consisting of a dielectric multi-fiber optic cable with an inline hermetic feedthrough for pressurized high-voltage insulators.

Advantagesof the SEDI-ATI solution

- Immunity to EMI/RFI,

- Gas-tight,

- Hermetic sealing,

- Dielectric materials to minimize ground potential,

- High bandwidth that supports high data rates over longer distances,

- Cables and connectors with a wide operating temperature range,

- Abrasion, vibration, and chemically resistant,

- Multi-fibers channels,

- Low insertion loss,

- Lighter and more compact than copper cables.

Related products

Fiber optic bundle assemblies for spectroscopy

Fiber-optic bundles are perfectly adapted to perform diffuse reflectance spectroscopic measurements.

M10-thread fiber-optic feedthrough for vacuum and pressure up to 600 bar

The KTRAV-M10 reconfigurable hermetic fiber-optic feedthroughs are suitable for vacuum and pressure applications up to 600 bars. They ensure a high level of hermeticity better than 10-10 mbar.l/s.

M12-thread fiber-optic feedthrough for vacuum and pressure up to 1000 bars

The KTRAV-M12 hermetic fiber-optic feedthroughs are suitable for vacuum and pressure applications up to 1000 bars. They ensure a high level of hermeticity better than 10-9 mbar.l/s.