CorrosiveAbrasive environments

Optical fiber assemblies resistant to hostile atmospheres

Thanks to its know-how and expertise, SEDI-ATI Fibres Optiques can offer optical fiber solutions based on optical fibers that are resistant to corrosive environments (chemical aggression) and abrasive environments (mechanical aggression).

Resistance to corrosive and abrasive environments

Optical fibers are sensitive to physical (abrasion) and chemical (corrosion) attack. If properly packaged, optical fibers can be installed in environments containing acids, solvents, gas, hydrocarbons, pretrochemical products, sand mud, rock or sea salt. Another alternative to silica fiber is sapphire fiber. Thanks to its extreme hardness and the inert nature of sapphire, this type of fiber can be used in extreme environments, and its crystalline structure allows transmissions over a wide spectrum (0.75 to 3.5 µm) and over a temperature range from cryogenic to + 1,000 °C. It can therefore be used without any problem in electrical insulators containing SF6 gas, or in oil wells, or in equipment in a marine environment for example.

The problem

Corrosive or abrasive chemicals can contain aggressive substances to the optical fiber and the assembly, as these products can degrade coatings (particularly polymer materials) and various components such as connectors. This can lead to failures in the optical connection, compromising both mechanical integrity and optical properties, to the point of rending the solution unusable and creating risks to the safety of people and equipment.

OurExpertise

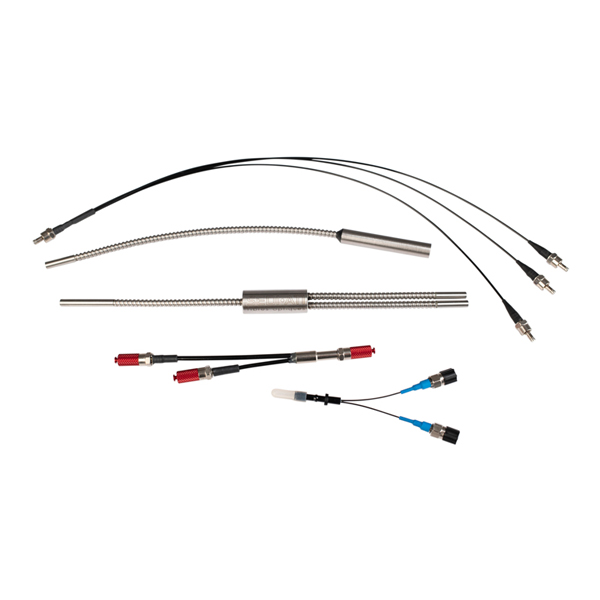

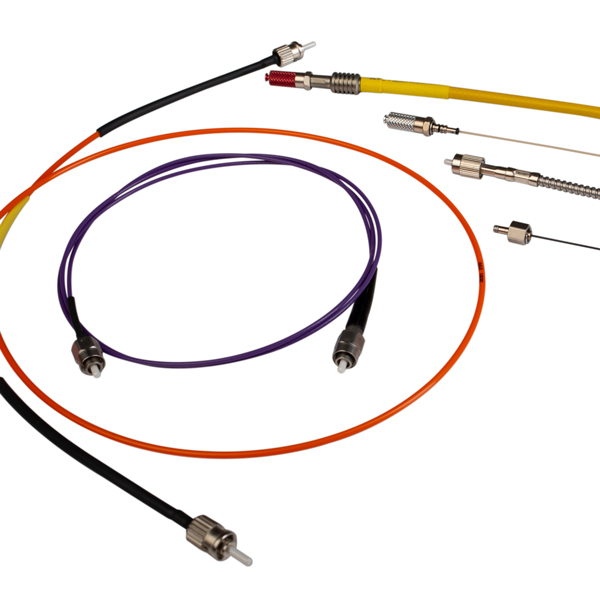

SEDI-ATI packages the optical fibers to protect them from corrosive and abrasive environments. We take particular care in selecting the materials that make up our fiber optic assemblies. They are selected for their mechanical and chemical properties, specific to different corrosive/abrasive environments For example, we prefer non-metallic synthetic coatings to protect the optical fibers against aggressive chemical attack And we use appropriate sealing technologies to ensure that our fiber optic assemblies are hermetically sealed in such environments. The fiber is selected from our wide range of aluminum, copper, carbon and acrylate-coated fibers. Finally, the sealing materials (epoxy, brazing, glass-soldering…) are taken into account to guarantee the hermeticity of the solution.

All our ranges of couplers, hermetic feedthroughs, bundles, special fiber optic cables and patchcords, connectors, multiplexers, etc, can be customized to meet your requirements.