Mechanical VibrationsShocks

Optical fiber assemblies withstanding mechanical vibrations and shocks

Thanks to its know-how and expertise, SEDI-ATI Fibres Optiques is able to offer you assemblies and solutions based on optical fiber, withstanding mechanical vibrations and shocks.

Resistance to extreme vibrations and shocks

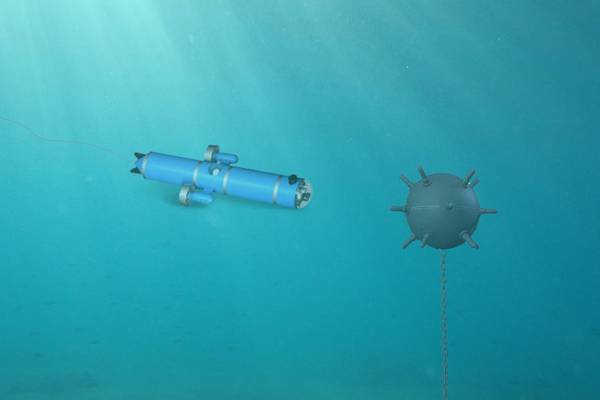

In an assembly based on optical fibers, the choice of the cladding to protect mechanically the fiber, and the anchoring technologies are essential to avoid mechanical vibrations and shocks. A “hardened” component will be sufficiently robust to enable the optical fiber to be installed in an environment subject to constant vibration. It can therefore be used in environments such as construction sites, heavy plant, offshore platforms or moving vehicles. It can also be found in defence, aerospace and industrial applications.

The problem

The main consequences of mechanical disruptions to uncured optical fiber assemblies are breakage or physical damage to the solution, disconnection of connectors, altered alignment and long-term degradation of performance.

OurExpertise

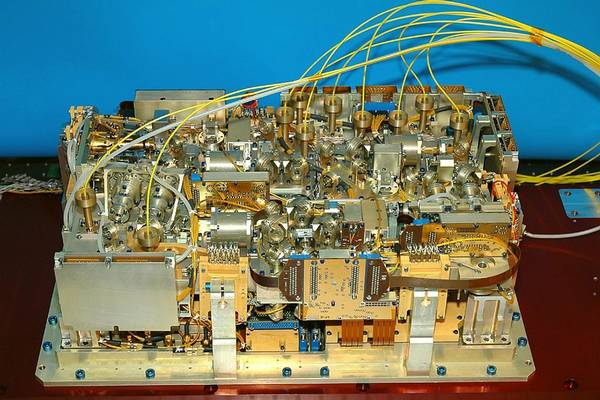

Our know-how and our expertise in extreme environments allow us to offer optical fiber assemblies withstanding mechanical stress such as shocks, vibrations, stretching, bending and accelerations of up to 50 G, thanks to specific assembly techniques. Raw materials, coatings and sheaths are selected to ensure that the product is functional and viable over time.

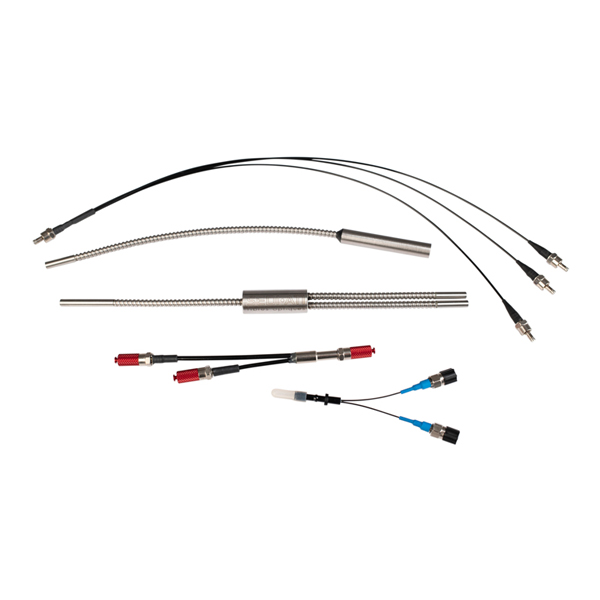

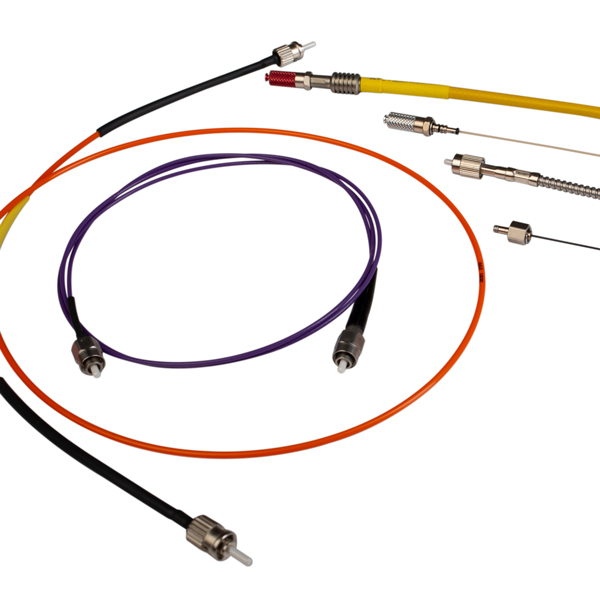

To provide you with a product capable of withstanding mechanical vibrations and shocks, the fiber is selected from a wide range of fiber with aluminum, copper, carbon, acrylate, etc, coatings. The sealing methods and materials used are adapted to the final application and the environment (epoxy, brazing, glass-soldering…). In addition to our range dedicated to space and aeronautics, which is all the more qualified for extreme conditions, almost all our special fiber optic cables and patchcords, hermetic feedthroughs, bundles, , connectors, multiplexers,… can be adapted to your final use.

Case studies

Product categories

-

Fiber-optic bundles, arrays and octopuses (4)

-

Disposable fiber-optic spools for tethered vehicles (5)

-

Optical connectors and fittings (3)

-

Fiber optic multimode couplers (4)

-

Multimode wavelength division multiplexers (3)

-

Hermetic fiber optic feedthroughs (11)

-

Specialty fiber optic cables and patchcords (9)