In-lineMonitoring

Fiber-optic solutions for in-line monitoring in industrial environments

SEDI-ATI supplies a set of high-directivity couplers and fiber-ruggedized patchcords with a stainless steel sheath and single-point connectors, for in-line monitoring of the thickness of glass bottles using confocal analysis.

MajorConstraints

The solution must whistand:

- Mechanical stress (accelerations, vibrations and bending radius),

- Dust,

- High-temperature.

TheChallenge

Integrating fiber-optics into a glass bottle thickness control system induces several technical and practical challenges due to the application environment. The assembly must withstand harsh conditions including speed, dust, high and fluctuating temperatures and vibration (mechanical stress).

Fiber-optics in the industrial sector

Optical fiber is increasingly used in industrial environments thanks to its ability to transmit data quickly, over long distances, without signal loss and with resistance to electromagnetic interference.

It can be used for :

- machine control and monitoring with a sensor function, for fault detection,

- video and audio surveillance by connecting surveillance cameras to industrial installations,

- factory automation and industrial networks to link machines, computers, sensors and control systems.

Checking the thickness of glass bottles

Checking the thickness of glass bottles in the industrial environment is a crucial step in ensuring the quality, safety and efficiency of the production process.

This non-destructive testing system helps to prevent breakage due to the thickness of the walls or their possible unevenness, to ensure product quality, to optimise costs and materials (management of raw materials and reduction of scrap rates), to confirm compliance with standards and regulations or to detect problems with the production machinery.

On leaving the furnace, after being formed and blown, the still hot glass bottles begin to cool gradually on conveyors. The bottles are then transported to the various inspection stages, including thickness measurement. Measurement sensors are positioned around the automated conveyor to measure the walls of the bottles and check that there are no bubbles inside.

The control station

An automatic control system (often using cameras or other machine vision devices) checks that each bottle is correctly positioned to ensure that the measurement is carried out accurately and uniformly on all the critical parts of the bottle (base, body, neck).

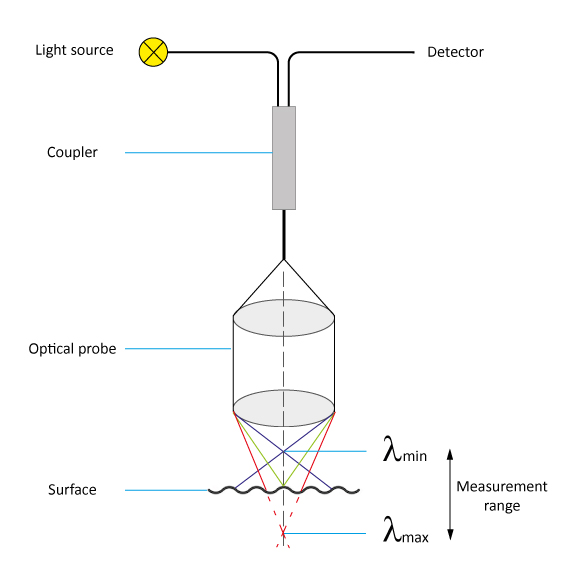

Optical or laser sensors project a beam of light onto the surface of the bottle and measure the reflected or refracted light. By comparing the distance travelled by the light between the different walls, it is possible to calculate the thickness. This system is highly accurate and is particularly suitable for high-speed production lines.

The measurements taken by the sensors are transmitted to a central computer system, which collects the data in real time. The system compares the thickness measurements obtained with the predefined production specifications. Tolerances are defined for each bottle, and any bottle whose thickness is outside these tolerances is identified as defective.

This defect can lead to a risk of breakage or an aesthetic quality problem. Finally, bottles that do not meet the quality criteria are automatically dismissed from the production line. This can be done using robotic arms that remove the non-compliant bottles from the conveyor.

SEDI-ATI expertise

SEDI-ATI Fibres Optiques offers high-directivity, achromatic and large-core fiber optic multimode couplers ideal for optical metrology and detection applications where the dynamic range of the sensor is a key parameter, or for spectroscopy applications (the light backscattered by the core of the component must be very small compared to the light backscattered by the object to be measured: increased dynamic range).

The solution provided consists of an assembly of high-directivity multimode couplers (HD or HDS for high-power UV or low-wavelength applications) for sensor functions, with ruggedized patchcords based on 50 µm-core optical fibers, with a stainless steel sheath and single-point connectors.

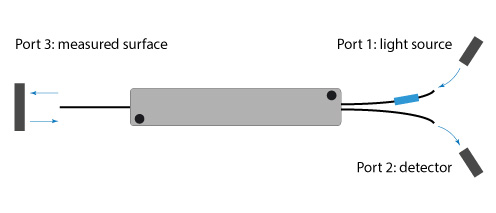

The coupler, in a round-trip configuration, sends light via the port 1, then recovers the light refracted or reflected by the surface in the port 3, and transmits it in real time for analysis via the port 2. The high-directivity is greater than 50 dB, ensuring maximum dynamic range for the sensor function (1/100,000 of light backscattered by the core of the component).

The couplers are then integrated into the customer’s chromatic confocal detector. The patchcords are offset accessories allowing you to move away from the measurement point..

All our products can be custom-made to suit your final applications.

SEDI-ATISolution

- High-directivity multimode couplers for sensor functions,

- Special reinforced patchcords with single-point connectors,

- Stainless steel sheaths.

AdvantagesSolution

- High directivity and uniformity,

- Modal Insensitivity,

- Highly achromatic,

- Wide spectrum,

- Versatile,

- Offset length: +10 meters par le biais de cordons associés au coupleur.

Related products

1×2 achromatic fiber optic multimode couplers

SEDI-ATI’s 1×2 achromatic fiber-optic multimode couplers have been designed for applications where wideband and achromaticity are required at an attractive cost.

1×2 high directivity fiber optic multimode couplers

SEDI-ATI’s high directivity multimode couplers are ideal for optical metrology and sensing applications where the dynamic range of the sensor is a key parameter.

1×2 large core fiber optic multimode couplers

SEDI-ATI’s large core fiber-optic multimode couplers are ideal for spectroscopy applications where large core optical fibers are required.

M10-thread fiber-optic feedthrough for vacuum and pressure up to 600 bar

The KTRAV-M10 reconfigurable hermetic fiber-optic feedthroughs are suitable for vacuum and pressure applications up to 600 bars. They ensure a high level of hermeticity better than 10-10 mbar.l/s.

M12-thread fiber-optic feedthrough for vacuum and pressure up to 1000 bars

The KTRAV-M12 hermetic fiber-optic feedthroughs are suitable for vacuum and pressure applications up to 1000 bars. They ensure a high level of hermeticity better than 10-9 mbar.l/s.

Threaded hermetic adapter up to 30 bars

The KTRAV-IP series is a hermetic adapter for pressure applications up to 30 bars.